-

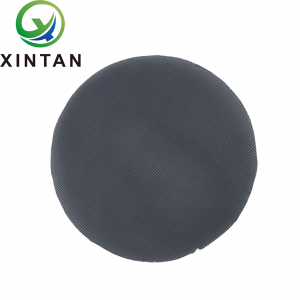

Ozone removal filter(Copper mesh carrier)

The ozone removal filter(Copper mesh carrier) developed by Hunan Xintan is an efficient ozone decomposition catalyst supported by copper wire mesh, which can decompose ozone into oxygen at room temperature. The appearance of ozone removal filter is black mesh, with the filter of 40 mesh /60 mesh /80 mesh /100 mesh or customized, the conventional size is a circular diameter of 5cm, other sizes can be customized according to user requirements. The product has the characteristics of light weight, high efficiency, low wind resistance, safe and no energy consumption, etc. It is mainly used for ozone removal and decomposition of precision electronic equipment, and can also be used for ozone analysis equipment to produce zero gas (standard gas).

-

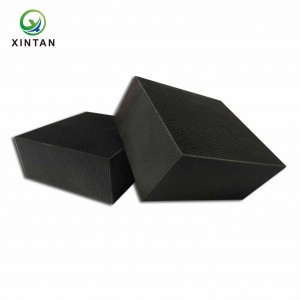

Hopcalite powder

Hopcalite powder is made by mixing a certain proportion of MnO2 with CuO. The catalyst is in black or dark brown powder form and is a catalyst that removes CO by oxidizing CO to CO2. The catalyst produced by Hunan Xintan has the characteristics of high efficiency, high catalytic activity, low cost and long service life. It can be used as raw material for producing carbon monoxide catalyst and ozone decomposition catalyst, and can remove carbon monoxide and ozone by itself. Used as coating material, coating on honeycomb carrier; as laboratory gas detection processing materials.

-

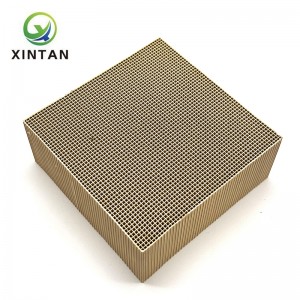

Honeycomb CO removal catalyst

Honeycomb CO removal catalyst uses cordierite honeycomb ceramic as a carrier and is a highly active catalyst prepared from a variety of rare earth metals. The catalyst produced by Hunan Xintan has the characteristics of high structural strength, strong surface coating adhesion, and is not easy to fall off. This catalyst can not only be used to treat carbon monoxide in flue gas, but also has high catalytic performance in chlorine-containing working conditions, and can be used for the treatment of chlorine-containing organic waste gas, and is widely used in the treatment of steel flue gas, lime kiln flue gas, waste incineration smoke and other smoke.

-

ozone O3 decomposition catalyst/destruction catalyst

ozone decomposition catalyst produced by Xintan is used to destroy ozone from exhaust emission. Made from manganese dioxide(MnO2) and copper oxide(CuO),it can decompose ozone into oxygen efficiently at ambient temperature and humidity,without any additional energy.It doesn’t include any activated carbon material.

It features high efficiency,stable performance and long working life(2-3years),Ozone destruction catalyst is widely applied in ozone generators ,commercial printers,waster water treatment ,disinfection and sterilization which is related to ozone application.

-

Modified honeycomb activated carbon

Modified honeycomb activated carbon is processed with coal charcoal powder, coconut shell charcoal powder, wood charcoal powder and other raw materials, and then through special physical and chemical treatment methods to change the characteristics of honeycomb activated carbon, so that it has large specific surface area, developed micropores, low fluid resistance, increased adsorption capacity, longer service life and other characteristics. The modified cellular activated carbon is divided into two kinds of products: water resistant and water resistant.

-

VOC catalyst with Noble metal

Noble-metal catalyst (HNXT-CAT-V01) uses bimetal platinum and copper as the active components and cordierite honeycomb ceramics as the carrier, a small amount of rare earth materials were added through special process to make the catalyst structure more stable, the surface active coating has stronger adhesion and is not easy to fall off. Noble-metal catalyst (HNXT-CAT-V01) has excellent catalytic performance, low ignition temperature, high purification efficiency, and good temperature resistance, suitable for conventional VOCs gas treatment, benzene treatment effect is good, and can be widely used in CO and RCO devices.

-

Hopcalite Catalyst/Carbon monoxide (CO) Removal Catalyst

Hopcalite catalyst, also named as Carbon monoxide (CO) removal catalyst, is used to remove CO by oxidizing CO into CO2.This catalyst adopts unique nanotechnology and inorganic non-metallic material formula, the main ingredients are CuO and MnO2,.The appearance is columnar particles.Under the condition of 20~200℃, the catalyst can catalyze the reaction of CO and O2 quickly and efficiently with free energy, converting CO into CO2,featuring high efficiency, energy saving and low maintenance cost. Xintan Hopcalite is widely applied in industrial gas treatment like nitrogen (N2) ,gas mask,refuge chamber and compressed air breathing equipment.

-

Carbon monoxide CO removal catalyst with Noble metal

Carbon monoxide CO removal catalyst produced by Xintan is noble metal catalyst(palladium) based on alumina carrier catalyst, used to remove H2 and CO in CO2 at 160℃~ 300℃。It can convert CO into CO2 and convert H2 into H2O. It doesn’t include MnO2 ,CuO or sulphur,so it can be safely used for CO purification in CO2,which is widely used for food industry.

Below is the key conditions for this precious metal catalyst.

1)Total sulfur content≤0.1PPM. (key parameter)

2) Reaction pressure < 10.0Mpa, the initial adiabatic reactor inlet temperature is generally 160 ~ 300℃. -

Copper oxide CuO Catalyst for removing oxygen from Nitrogen

CuO Catalyst by Xintan is used to remove oxygen from nitrogen or other inert gases like helium or argon, Made of high-percentage copper oxide(CuO) and inert metal oxides, it can convert oxygen into CuO efficiently, without any additional energy. It doesn’t contain any dangerous material.Below is the reaction equation catalytic deoxygenation :

CuO+H2=Cu+H2O

2Cu+O2=2CuO

Because of high efficiency, It’s widely used for gas treatment. -

Ozone removal filter/Aluminum honeycomb ozone decomposition catalyst

Ozone removal filter (Aluminum honeycomb ozone decomposition catalyst )adopts unique nano technology and inorganic non-metallic material formula. With the carrier of aluminum honeycomb, the surface is saturated with active ingredients; It can quickly and efficiently decompose medium and low concentration ozone into oxygen under room temperature, without additional energy consumption and no secondary pollutants. The product features light weight, high efficiency and low wind resistance. Our aluminum honeycomb ozone decomposition catalyst can be used in household disinfection cabinets, printers, medical equipment, cooking devices, etc.

-

Palladium hydroxide catalyst Noble metal catalyst

The Palladium hydroxide catalyst developed by Hunan Xintan uses alumina as the carrier and noble metal palladium as the raw material. Palladium hydroxide is an important inorganic compound, the molecular formula is Pd(OH)2. It can catalyze many important chemical reactions, such as hydrogenation, hydrogenation, dehydrogenation, oxidation, etc., widely used in pharmaceutical, chemical, energy and other fields. In addition, palladium hydroxide can also catalyze the synthesis and oxidation of organic compounds, and is one of the important catalysts in organic synthesis. Palladium hydroxide is also an important raw material for preparing palladium and palladium alloys.