Hopcalite powder

Hopcalite powder is made by mixing a certain proportion of MnO2 with CuO. The catalyst is in black or dark brown powder form and is a catalyst that removes CO by oxidizing CO to CO2. The catalyst produced by Hunan Xintan has the characteristics of high efficiency, high catalytic activity, low cost and long service life. It can be used as raw material for producing carbon monoxide catalyst and ozone decomposition catalyst, and can remove carbon monoxide and ozone by itself. Used as coating material, coating on honeycomb carrier; as laboratory gas detection processing materials.

Main parameters of hopcalite powder

| Appearance | Black or dark brown powder |

| Ingredients | MnO2, CuO |

| Cu:Mn | 0.86~0.95 |

|

Size |

200mesh or customized |

|

Length |

2-5mm or 5-10mm or Customize (hopcalite particle) |

| Bulk density | 0 .45~0.50 g/ ml |

| Surface area | >180 m2/g |

| Moisture content | ≤5% |

Advantage of hopcalite powder

A)High activity and high efficiency. Xintan hopcalite powder has highly active formulation that effectively converts CO to CO2. The active ingredient content of hopcalite powder is more than 85%, and the specific surface area is higher than 180m2/g, which can effectively improve the catalytic efficiency of the product.

B)Long service life. The life of Xintan hopcalite powder can reach 2-3 years.

C)Low cost. The catalyst can oxidize CO gas at room temperature.

Shipping,Package and storage of hopcalite powder

A)Xintan can deliver cargo below 5000kgs within 7 days.

B)30kg or 40kg into Iron drum.

C)Keep dry when storing and seal iron drums.

D)Regeneration condition: The catalyst can be regenerated at a temperature of 150-200℃.

Applications of hopcalite powder

A)As raw material for the production of carbon monoxide removal catalyst and ozone decomposition catalyst;

B)Used to eliminate carbon monoxide and ozone;

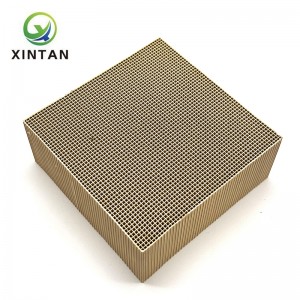

C)Used as coating material, coating on honeycomb carrier;

D)As laboratory gas detection processing materials.

Technical service

Based on working temperature, humidity, gas flow and CO concentration, Xintan team can advise you on the quantity of Hopcalite powder required for your equipment. In addition, it is recommended to control the humidity of the working environment below 10%. High humidity working environment will reduce the use of catalyst effect, shorten the service life. When the humidity is greater than 10%, it can be used with desiccant.